Inflationary pressure, price increases and force majeure are concepts that supply chain professionals are becoming intimately familiar with these days. While this month’s purchasing managers index (PMI) showed some deceleration in manufacturers’ input costs, broad gauges of inflation, such as the consumer price index, are the highest they’ve been in four decades. Supply shortages and disruptions remain, more than two years after the start of the global pandemic.

Against this backdrop, suppliers are asking for the one thing that procurement professionals most dread: compensation for inflation. Managing these requests while avoiding strains in supplier relations can be tricky.

Given this, we thought it would be a good time to share some best practices we’ve developed at ProcureAbility from our firm’s more than 25 years of experience focused on supporting procurement teams. We’ll break them down into four areas for managing such requests—responding to an initial request, processing a request, requesting supplier information, and reaching an agreement—with an eye toward providing a basic roadmap for responding.

Responding to an initial request

Supplier price increase requests can come in an email, a phone call or, in rare cases, an update to invoices. It’s important to acknowledge that you’ve received the request from the supplier and let them know that you will respond within a specified amount to time.

This is all about managing expectations while sending a signal that you’re giving their request the attention it deserves. The more transparent you can be about how much time you will need to respond, and what information you need to gather to respond, the better. This will also put the issue squarely on your to-do list so it doesn’t snowball and become a bigger issue that compromises the supply base.

Now, it might be that you feel there is enough information to authorize an acceptance or rejection of their proposal right off the bat. The supplier might even push you and your organization to decide quickly, using whatever leverage they have. Resist this. An immediate rejection could be perceived as a lack of care in maintaining the relationship. Taking the time your organization needs to fully assess the request sends the opposite signal. It says your organization is methodical and analytical in processing such requests and won’t jump the gun—or be pushed around.

Processing a request

Make sure you know what the supplier is asking of your company. It might be a material pass-through or an adjustment for higher labor costs or freight compensation. It could be a combination of these factors. It’s important to understand the drivers of the request so your management team can make the best decision.

Work to understand what financial impact it will have on your company’s bottom line if accepted, and how you might be able to absorb it. Maybe the sales team has agreed to pass such increases onto the customer. If that’s not the case, you need to know now so you can assess how the price increase is likely to impact your internal financial goals. That information could prove quite valuable if you need to make a case for rejecting the request.

Be sure not to take all of this on by yourself. Alert your team, bringing in your category manager, sales team, and other stakeholders. They might be able to provide insights into the types of information—such as indexing data and broad inflationary trends—you can use as a benchmark against the requested price increase.

Your team can also help you understand how critical the supplier is to your business and the level of negotiating leverage. What is the size of this supplier relative to your company? Are they sole sourced? Is there more upcoming business to award? These are the types of question you and your team should be asking as you consider the request and weigh how aggressive to be in responding.

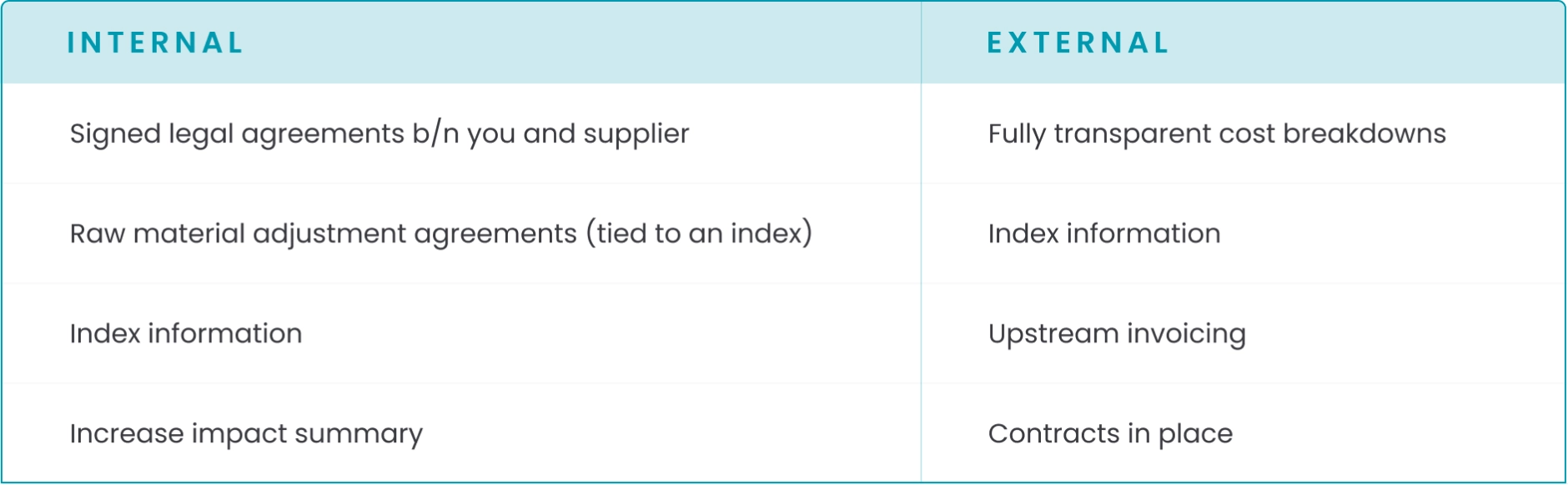

In pursuit of these answers, create two separate lists, one containing items needed internally and one listing items needed from the supplier. Some examples are listed below:

Requesting supplier information

When seeking information from the supplier, be sure to emphasize how important they are as a partner. This is especially important when dealing with sole-source providers, but all suppliers should be made to feel important.

Make it abundantly clear that you won’t be able to decide on the request until you’ve received the information you seek. Avoid setting a deadline until you have these items. When it is furnished, make sure you understand what they have presented and ask questions if necessary.

Before you move into your final negotiation on the request, ensure the supplier has explored all other avenues to mitigate cost. There may be an alternative, mutually beneficial outcomes that haven’t been offered, or perhaps haven’t been considered, by the supplier. Questions you might consider asking to this end would include: Is there room in other areas for cost reduction? What about alternative materials or new processes?

Reaching an agreement

After you have reviewed all the information that you requested and received, create a document to help guide your negotiations with the supplier. Your discussions with the supplier should stress the impact that their request will have on the company, so it’s important to fully understand and explain the financial outcomes tied to accepting or declining the request or finding an alternate solution.

Remember: neither your company nor the supplier should have to assume the full burden of the cost increase. In making your case, cite the information that supports compromise. Avoid framing the negotiations from the standpoint of winning or losing.

When making your counter proposal, consider whether the terms might be adjusted to buy you some relief. For instance, you might grant their increased compensation for a limited amount of time or start it at a future date. You might also consider capping inflationary increases to a specified percentage going forward or using index agreements as a guide.

Whatever path you propose, explain your reasoning and draw support from the information you were provided. If you’ve followed the steps above, this part of the process should go smoothly. If it doesn’t, it might be time to reappraise your relationship with the supplier. Every successful company has successful partners who want to work with you, not exploit you. If you find you’re not dealing with an honest broker, it’s probably time to move on.